Linear Motion

We have figured out the components we need to mount a motor, so now it's time to decide on the other critical parts of the linear motion system. You have more choices here than days in a month. For the Crikey 2010 (yes, that's it's name even though it was built in 2009) 12mm linear slides where used. There are other interesting choices available. For example:

V-Groove system from Bishops-Wisecarver or the U-Groove Guide Bearings, they are available from VXB Bearings.

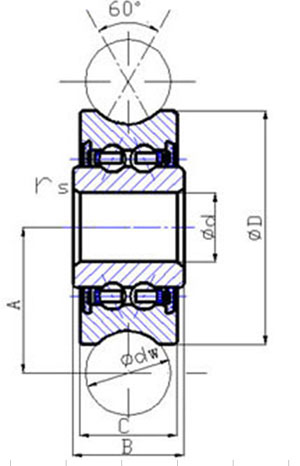

The most common linear motion systems for home built CNC systems use linear shafting with linear bearings. Linear shafting flexes under load which becomes more problematic the longer the shaft becomes. Purists will have you believe that this is a poor choice. Depending on your overall length and shaft diameter, this type of motion system may be suitable for your application. There are many variations that use open linear bearings which allow you to provide extra support underneath the linear shaft. With the extra support, flexing can be significantly reduced. A set of 20mm x 30" hardened steel shafts (qty 2) with a set of linear bearings (qty 4) will run in the region of $80. Now add in the shaft supports and bearing blocks and you very quickly approach $120 - and that's just for one axis. Obviously as the shafting diameter is reduced, the cost reduces but so does the cutting load the router is able to withstand without flexing too much.

www.vxb.com has 44" (and longer) linear guideway systems similar to the above. For the 16mm shafting, a 44" length will run you around $87, with the trucks coming in at around $27 each. You will need to run your own cost benefits analysis to see what works for you. Each axis will require 2 linear guideways and 2 trucks. Money adds up fast when you play with linear motion systems.

I found an ebay vendor (Toolssales) who packages a set of parts as kits at good prices. The parts ship from Hong Kong so you'll probably need to be patient. I have not bought from this vendor so do your homework regarding ebay feedback reviews.

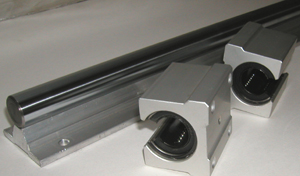

I found an ebay vendor (Toolssales) who packages a set of parts as kits at good prices. The parts ship from Hong Kong so you'll probably need to be patient. I have not bought from this vendor so do your homework regarding ebay feedback reviews. What I recommend for this design are 15mm linear slides. New slides are very precise and can match the prices of linear shafting. The slides I'm using have a 12mm rail and are 26" and 21"long made by IKO. I would have preferred 15mm slides but you take what you can get and the 12mm slides have held up very well over the 2 years of operation cutting aluminum and wood.

Automation Overstock has very good prices on linear slides. The manufacturer is HIWIN. : http://www.automation-overstock.com/

Automation Overstock has very good prices on linear slides. The manufacturer is HIWIN. : http://www.automation-overstock.com/For a single axis, you need 4 bearing blocks and 2 rails. Using the 15mm parts from Automation Overstock, you will end up at around $160 per axis or $480 for the X,Y and Z axis. Roughly the same as large diameter linear shafting and in my opinion a better choice. If you scale up to the 20mm system, you will end up at around $600 for all 3 axis. I'll say it again. Motion systems cost money. Precision components don't come cheap.

| Bearing blocks and rail |

That's all for now. With the slides selected and on-hand, it is time to move on to the base frame components and assembly.

I found some more information on this website about this is a great device: http://www.directindustry.com/industrial-manufacturer/linear-guide-61089.html

ReplyDelete